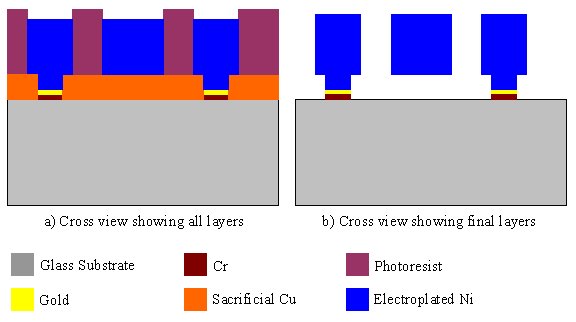

Ni electroplating process has successfully utilized the fabrication of the sensors. Figure 1 shows the cross section showing all the layers in Ni electroplating process. We are using Cu sacrificial layer and thick photoresist (SJR5740) for the structure formation. We have achieved nonlinearity of 0.29 %, an average noise floor of 487 µg/.Hz (in 500Hz bandwidth), and a bias instability of 13.9 mg for our accelerometers. We are currently trying to improve the performances of the Ni electroplated accelerometers with new designs and new readout circuits and also with better fabrication facilities to have better quality Ni structural layers.

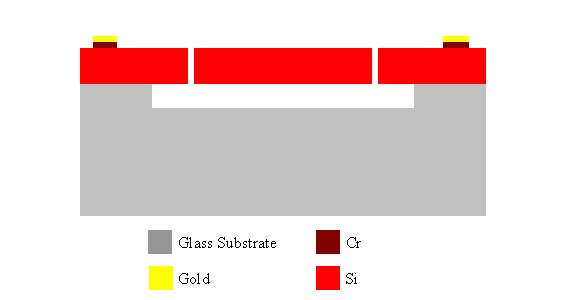

DRIE process is rather newer process compared to electroplating, and we are currently optimizing the DRIE process. Figure 2 shows the cross section view showing all the layers in DRIE process. We are using glass substrates anodic bonded to Si wafers. The structures are formed by etching Si wafer properly with the DRIE machine. Due to high aspect ratio etch facility of DRIE machine, the performances of these accelerometers are expected to be at least 4 times better than of the Ni electroplated accelerometers. Another advantage of this process compared to Ni electroforming process is better reliability, due to using Si structural material instead of a metal.

Fig. 1: Cross-section view showing all the layers in Ni electroplating process.

Fig. 2: Cross-section view showing all the layers of DRIE process.